Why is quality control so important in the apparel industry?

When a consumer walks into the retail store, picks a pair of 32W x 32L straight fit jeans off the shelf, and goes to the register, they expect it to fit the same way it did the last time they bought a pair of those same straight fit jeans.

When it comes to garment production, shipment-to-shipment variances in size can have a major impact on how your brand is perceived, and clothing that doesn’t stand up to normal usage is bad for your image as well.

These kinds of variances can lead to increased returns or a decline in sales.

That is why it is critical that you have proper quality control procedures in place to catch garment defects before your orders are shipped to you.

How do you ensure the quality of your finished garments?

That is what we’re talking about in this article.

Your Tech Pack Lays the Groundwork for Quality Control

In order to achieve consistency with your finished products, you first need to have clear specifications that serve as standards to which you can compare all finished goods.

This is why your tech pack is important.

A tech pack is essentially a blueprint created by your designer that provides instructions for the manufacturer to use during the production process.

According to Techpacker, a tech pack is usually made up of the following components:

- Technical Sketches

- Sample Sizes and Measurements

- Construction Details

- Bill of Materials (BOM)

- Stitches and Seams

- Branding Artwork

- Measurement Specs

- Point of Measurement (POM)

- Diagrams

Having all of these bases covered in your tech pack allows you to provide clear specifications to a third-party inspection company as well.

An inspection services provider can serve as your QC team at factories overseas and will conduct inspections on your behalf.

You can provide them with your completed tech pack and they will use it to help you ensure that your garments meet specific quality standards.

How are these inspections conducted?

Garment Inspections: How They are Conducted

Working with a third-party inspection company to conduct Final Random Inspections helps ensure that orders meet your quality expectations before they leave the factory and are shipped to you.

You will need to work with your inspection partner to develop a quality inspection manual, provide measurements for all sizes of each of your products, and develop an inspection checklist.

Inspections are conducted based on the AQL standard, which is used to determine how many pieces of clothing to inspect.

Once the appropriate number of pieces is selected for inspection, the inspector can begin going through the checklist and start taking measurements.

Taking Measurements During an Inspection

When it comes to garments, measurements are incredibly important.

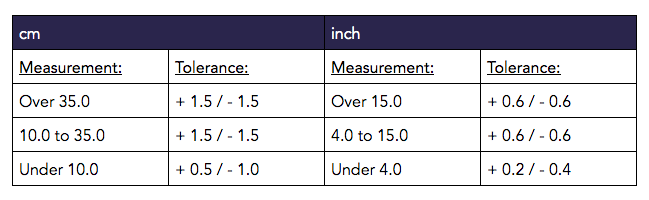

As such, items will be picked and measured, but it is important that you decide on specific tolerances like the ones you can see in the table below.

In this example, measurements over 35cm long have a tolerance of +/- 1.5cm.

That means that if an XS polo shirt is supposed to have a half-chest measurement of 48 cm and a QC inspector measures a piece at 49 cm, the piece is considered acceptable. However, If it measures 50cm, the shirt is rejected.

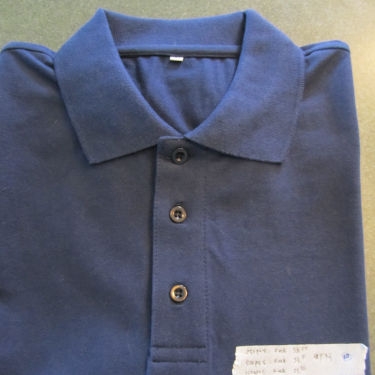

Some examples of common Points of Measurement (POM) that might be taken for a polo shirt include:

- 1/2 Chest

- 1/2 Hem

- CB Length

- Hem Drop

- Shoulder

- Sleeve

- 1/2 Armhole

- 1/2 Bicep

- 1/2 Cuff

- 1/2 Collar Length

- Center Front Opening

- Center Back Collar

For each Point of Measurement, all sizes such as XS, S, M, L, and XL need to have measurements specified.

Care / Size Label Inspection

Another key part of a garment inspection is performing label checks.

After determining the AQL sample size, garments are set aside for measurement, label checks, fabric and physical tests.

Each garment needs to have the correct information on it, such as the correct size and the right care instructions, to ensure compliance with regulations.

If the wrong symbols or instructions are used, the shipment may fail inspection.

Physical Tests

The following physical tests are generally conducted to ensure product quality:

- Stretch Test – This involves testing straps or elastic bands to see if they stand up to pulling or stretching.

- Pull Test – Zippers or buttons are pulled for 10 seconds with a gauge to determine if they stay attached.

- Fatigue Test – An accessory is used repeatedly to determine if it stands up to normal usage. For example, a button is snapped or a zipper is pulled 50 times.

If garments don’t pass these tests, the shipment may fail inspection.

Fabric Tests

The following fabric tests are usually conducted:

- Stitches Per Inch Check – The inspector counts the number of stitches over one inch of the garment to determine durability.

- Fabric Composition Check – The inspector uses hand feel to determine if the fabric seems to match the appropriate composition.

- Fabric Grams Per Square Meter (GSM) Check – The inspector cuts out a piece of fabric and weighs it to see if the weight matches specifications.

If any of these tests are not passed, the shipment may fail inspection.

Lab Tests: An Additional Quality Control Option

In addition to conducting inspections, you can also send completed garments out for lab testing.

Garments can be tested for colorfastness to washing, crocking (rubbing), light, perspiration, or water.

The lab can also conduct piling tests, do fiber analysis, test for flammability, and more.

Together with inspections, lab tests can give you a well-rounded QC program that helps ensure your garments are compliant with regulations and meet your high brand standards.

Summary: Quality Control Procedures Help Importers Avoid Poor Quality Garment Shipments

Having proper quality control procedures in place is important to any brand that wants to have long-term success in the marketplace.

Third-party quality inspections can help brands to accomplish this.

Once a tech pack is provided to the QC company, a quality manual and an inspection checklist can be developed.

Inspections can be conducted, which include procedures such as measurement taking, label checking, and conducting physical tests and fabric checks.

Sending garments to a third-party lab can help you conduct additional tests to ensure quality, safety, and compliance.

Because it is important to invest in the quality of your products, we recommend you read the following white paper.